What are the Product Standards for Chip Resistors?

I. Introduction

In the world of electronics, chip resistors play a crucial role in circuit design and functionality. These tiny components, often no larger than a grain of rice, are essential for controlling current flow and voltage levels in various applications. As technology advances and the demand for reliable electronic devices increases, the importance of product standards for chip resistors cannot be overstated. This article aims to explore the significance of these standards, the key parameters involved, and the challenges faced by manufacturers in meeting them.

II. Understanding Chip Resistors

A. What are Chip Resistors?

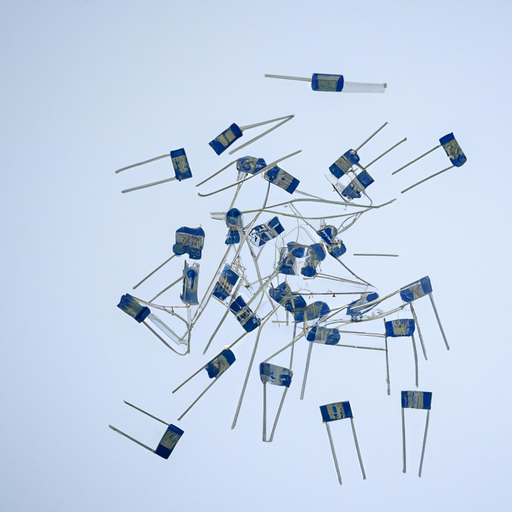

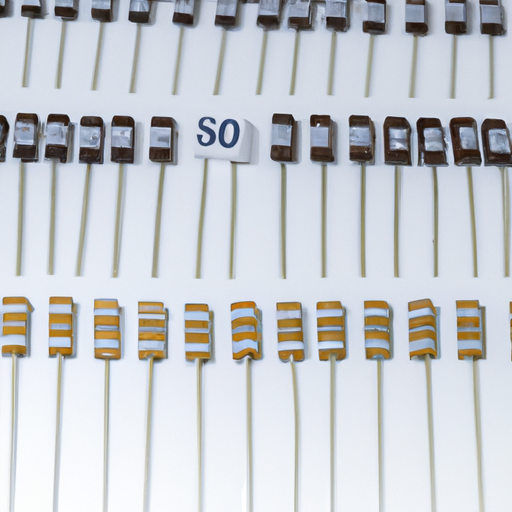

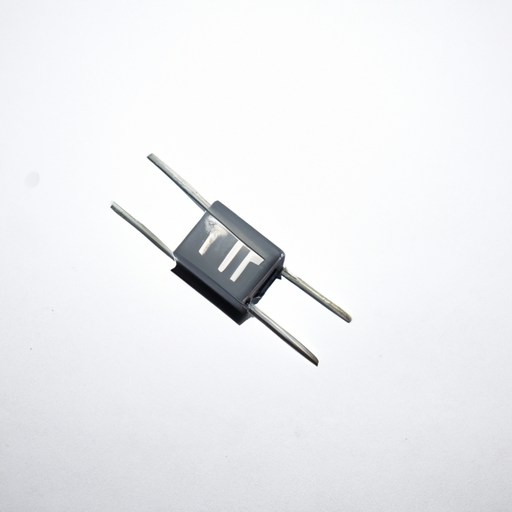

Chip resistors are surface-mounted devices (SMDs) that provide resistance in electronic circuits. They are typically constructed from a ceramic substrate coated with a resistive material, which can be either thick film, thin film, or wirewound.

1. **Description and Construction**: The construction of chip resistors involves a combination of materials that determine their electrical properties. The resistive element is usually made from a metal oxide or a carbon film, while the substrate is often made from high-quality ceramic to ensure stability and reliability.

2. **Types of Chip Resistors**:

- **Thick Film Resistors**: These are the most common type, known for their cost-effectiveness and versatility. They are made by printing a resistive paste onto a ceramic substrate.

- **Thin Film Resistors**: These offer higher precision and stability, making them suitable for applications requiring tight tolerances.

- **Wirewound Resistors**: These are constructed by winding a metal wire around a ceramic core, providing high power ratings and excellent performance in high-frequency applications.

B. Applications of Chip Resistors

Chip resistors are used in a wide range of applications, including:

1. **Consumer Electronics**: From smartphones to televisions, chip resistors are integral to the functioning of everyday devices.

2. **Automotive**: In modern vehicles, chip resistors are used in various systems, including engine control units and infotainment systems.

3. **Industrial Equipment**: Chip resistors are essential in machinery and equipment used in manufacturing and automation.

4. **Telecommunications**: They play a vital role in communication devices, ensuring signal integrity and performance.

III. Importance of Product Standards

Product standards are essential for ensuring the quality and reliability of chip resistors. They serve several critical functions:

A. Ensuring Quality and Reliability

Standards provide a benchmark for manufacturers, ensuring that their products meet specific performance criteria. This is crucial for maintaining the reliability of electronic devices, especially in critical applications like automotive and medical equipment.

B. Facilitating International Trade

With the globalization of the electronics market, product standards help facilitate international trade by ensuring that components from different manufacturers can work together seamlessly. This is particularly important for companies that source components from various countries.

C. Enhancing Safety and Performance

Adhering to established standards helps enhance the safety and performance of electronic devices. By ensuring that chip resistors can withstand environmental stresses and operate within specified parameters, manufacturers can reduce the risk of failures and accidents.

D. Compliance with Regulatory Requirements

Many industries are subject to strict regulatory requirements. Compliance with product standards helps manufacturers meet these regulations, avoiding potential legal issues and ensuring market access.

IV. Key Product Standards for Chip Resistors

A. International Standards

1. **IEC (International Electrotechnical Commission)**: The IEC sets international standards for electrical and electronic devices.

- **IEC 60115 Series**: This series covers the general specifications for fixed resistors, including testing methods and performance criteria.

- **IEC 60068 Series**: This series addresses environmental testing, ensuring that components can withstand various conditions.

2. **ISO (International Organization for Standardization)**: ISO standards focus on quality management systems.

- **ISO 9001**: This standard outlines the criteria for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

B. National Standards

1. **ANSI (American National Standards Institute)**: ANSI develops standards for various industries in the United States, including electronics.

2. **JIS (Japanese Industrial Standards)**: JIS standards ensure the quality and safety of products in Japan.

3. **DIN (Deutsches Institut für Normung)**: DIN standards are crucial for ensuring quality and safety in German manufacturing.

C. Industry-Specific Standards

1. **Automotive Standards (e.g., AEC-Q200)**: These standards ensure that components used in automotive applications can withstand the harsh conditions of vehicle operation.

2. **Military Standards (e.g., MIL-PRF-55342)**: These standards specify the performance requirements for resistors used in military applications, ensuring reliability in critical situations.

V. Key Parameters and Testing Methods

A. Electrical Characteristics

1. **Resistance Value and Tolerance**: The resistance value is the primary specification for chip resistors, with tolerance indicating the allowable deviation from this value.

2. **Temperature Coefficient of Resistance (TCR)**: TCR measures how much the resistance changes with temperature, which is crucial for maintaining performance in varying conditions.

3. **Power Rating**: This parameter indicates the maximum power the resistor can handle without failure.

B. Environmental and Mechanical Testing

1. **Temperature and Humidity Testing**: These tests assess the resistor's performance under extreme environmental conditions.

2. **Vibration and Shock Testing**: These tests ensure that the resistor can withstand mechanical stresses during operation.

3. **Thermal Cycling**: This testing evaluates the resistor's ability to endure rapid temperature changes.

C. Reliability Testing

1. **Life Testing**: This involves subjecting the resistor to prolonged use to assess its longevity.

2. **Burn-in Testing**: This process involves running the resistor at elevated temperatures to identify early failures.

3. **Failure Rate Analysis**: This analysis helps manufacturers understand the reliability of their products over time.

VI. Compliance and Certification

A. Importance of Compliance with Standards

Compliance with product standards is essential for manufacturers to ensure their products are safe, reliable, and of high quality. It also helps build trust with customers and stakeholders.

B. Certification Processes

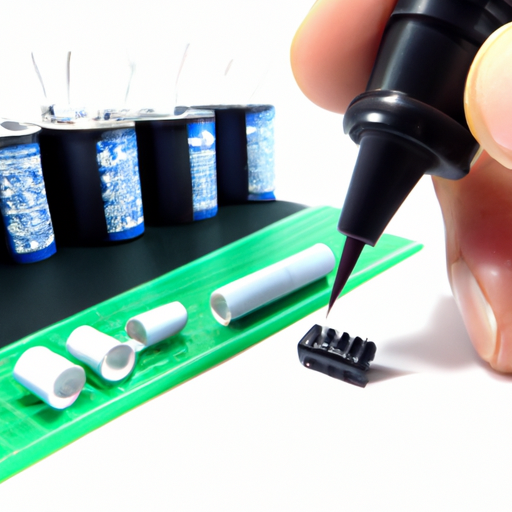

1. **Testing Laboratories and Accreditation**: Independent testing laboratories play a crucial role in verifying compliance with standards. Accreditation ensures that these labs meet specific quality criteria.

2. **Documentation and Traceability**: Manufacturers must maintain thorough documentation of their compliance efforts, including test results and certifications.

C. Role of Manufacturers in Ensuring Compliance

Manufacturers are responsible for implementing quality control measures and ensuring that their products meet the required standards. This includes regular testing, documentation, and continuous improvement processes.

VII. Challenges in Meeting Product Standards

A. Technological Advancements and Evolving Standards

As technology evolves, so do the standards. Manufacturers must stay updated on changes and adapt their processes accordingly, which can be challenging.

B. Cost Implications for Manufacturers

Meeting product standards often requires significant investment in testing, quality control, and certification processes, which can impact profitability.

C. Global Supply Chain Considerations

Manufacturers must navigate complex global supply chains, ensuring that all components meet the necessary standards, which can be a logistical challenge.

VIII. Future Trends in Chip Resistor Standards

A. Increasing Demand for Miniaturization

As electronic devices become smaller and more compact, the demand for miniaturized chip resistors will continue to grow. Standards will need to evolve to accommodate these changes.

B. Rise of Smart Technologies and IoT

The proliferation of smart devices and the Internet of Things (IoT) will drive the need for more advanced chip resistors, necessitating updates to existing standards.

C. Sustainability and Environmental Considerations

As the industry shifts towards more sustainable practices, standards will increasingly focus on environmental impact, including the materials used in chip resistors and their end-of-life disposal.

IX. Conclusion

In conclusion, product standards for chip resistors are vital for ensuring the quality, reliability, and safety of electronic components. These standards facilitate international trade, enhance performance, and ensure compliance with regulatory requirements. As technology continues to advance, the importance of these standards will only grow, shaping the future of the electronics industry. Manufacturers must remain vigilant in their efforts to meet these standards, ensuring that they can deliver high-quality products that meet the demands of an ever-evolving market.

X. References

1. IEC 60115 Series - International Electrotechnical Commission.

2. ISO 9001 - International Organization for Standardization.

3. AEC-Q200 - Automotive Electronics Council.

4. MIL-PRF-55342 - Military Specifications.

5. ANSI, JIS, DIN standards documentation.

6. Industry publications on chip resistors and standards.