Information

dict2_description

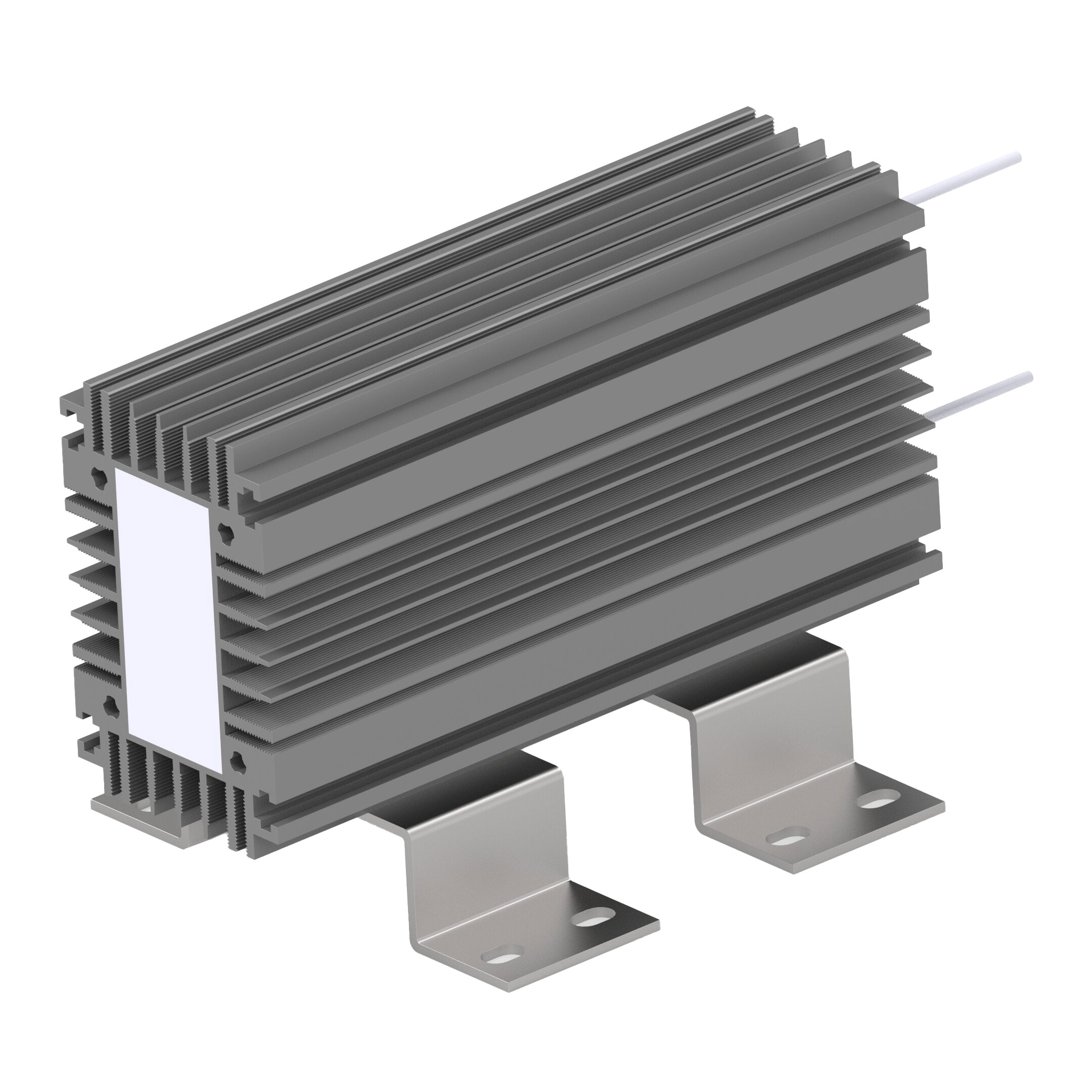

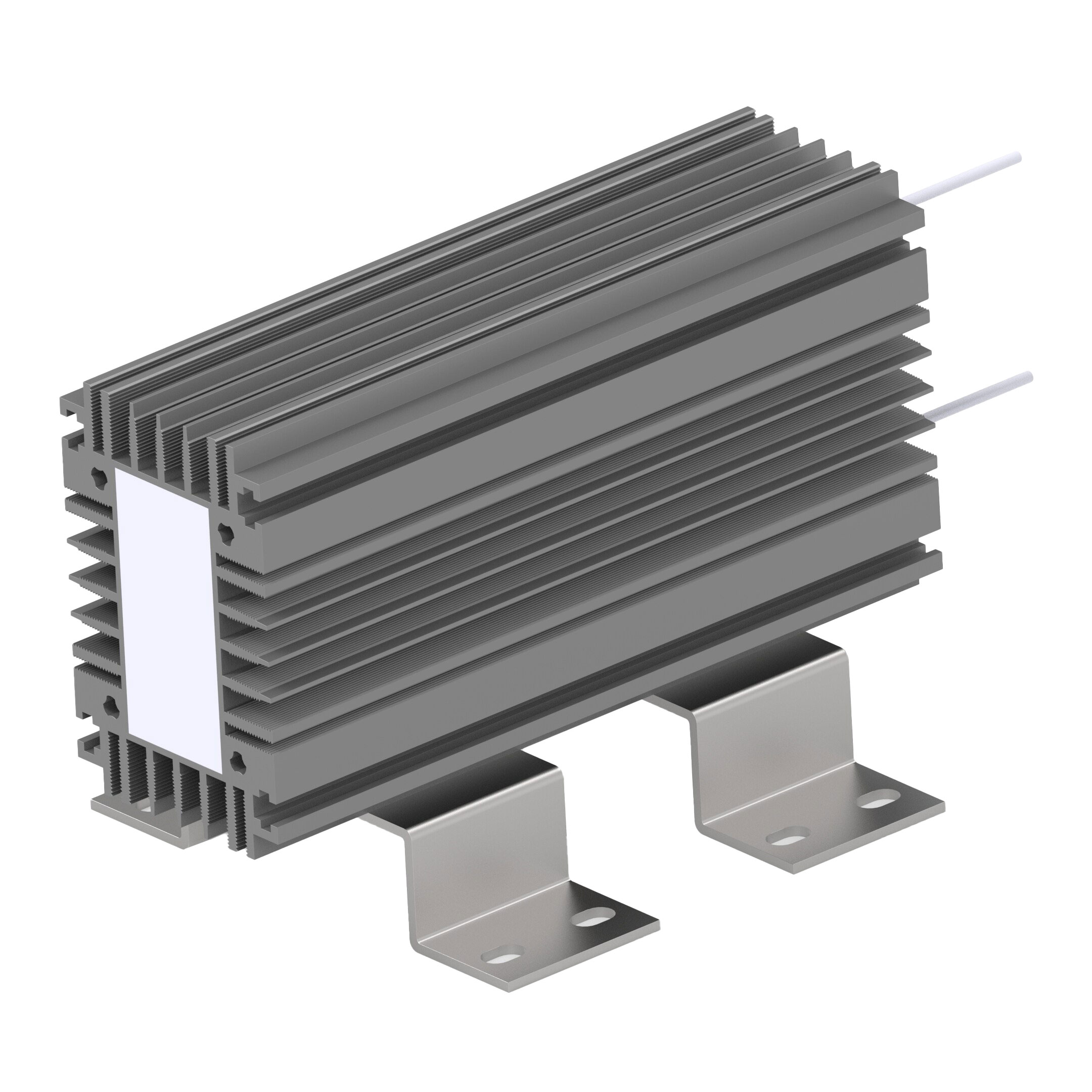

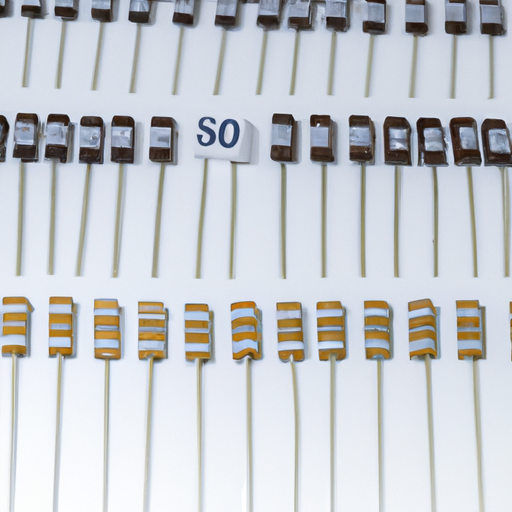

What are the product standards for chip resistors?

2024-10-19

1

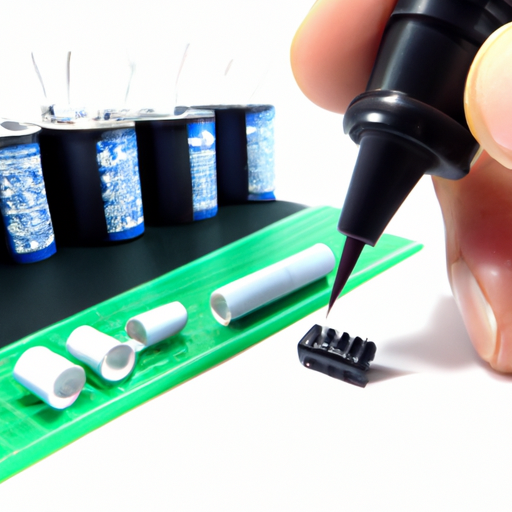

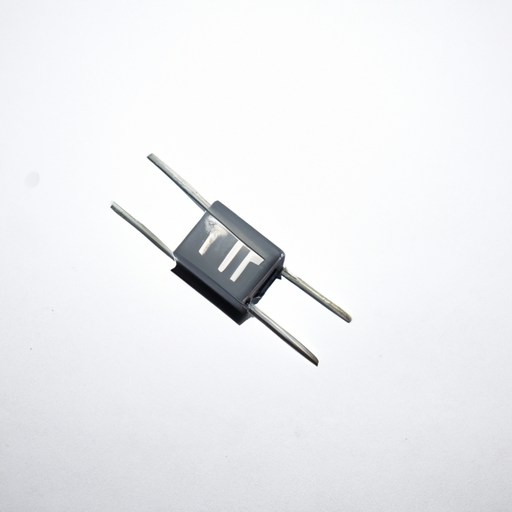

What is the symbol of the resistor?

2024-10-18

0

dict3_title

dict3_description