How to Choose Off-the-Shelf Thick Film Resistors

I. Introduction

In the world of electronics, resistors play a crucial role in controlling current flow and ensuring circuit functionality. Among the various types of resistors available, thick film resistors are widely used due to their unique properties and advantages. This blog post aims to guide you through the process of selecting off-the-shelf thick film resistors, highlighting key specifications, environmental considerations, performance characteristics, and more. By the end of this article, you will have a comprehensive understanding of how to choose the right thick film resistor for your electronic applications.

II. Understanding Thick Film Resistors

A. What are Thick Film Resistors?

Thick film resistors are passive electronic components made by printing a resistive material onto a substrate, typically ceramic. The manufacturing process involves screen printing a paste containing metal oxides onto the substrate, followed by a firing process that sinters the material, creating a stable and durable resistor.

1. Composition and Manufacturing Process

The resistive layer is composed of a mixture of conductive and insulating materials, which determines the resistor's value. The thickness of the printed layer is what distinguishes thick film resistors from thin film resistors, leading to different performance characteristics.

2. Characteristics and Properties

Thick film resistors are known for their high stability, reliability, and versatility. They can be produced in a wide range of resistance values and power ratings, making them suitable for various applications.

B. Advantages of Thick Film Resistors

1. Cost-effectiveness

One of the primary advantages of thick film resistors is their cost-effectiveness. They are generally less expensive to manufacture than thin film resistors, making them an attractive option for budget-conscious projects.

2. High Stability and Reliability

Thick film resistors exhibit excellent thermal stability and reliability, which is essential for maintaining performance in demanding environments. Their robust construction allows them to withstand mechanical stress and temperature fluctuations.

3. Versatility in Applications

These resistors are versatile and can be used in a wide range of applications, from consumer electronics to industrial equipment. Their adaptability makes them a popular choice among engineers and designers.

C. Common Applications of Thick Film Resistors

Thick film resistors are commonly found in various applications, including:

1. Consumer Electronics

From televisions to smartphones, thick film resistors are integral components in consumer electronics, helping to regulate current and ensure proper functionality.

2. Automotive Systems

In automotive applications, thick film resistors are used in control systems, sensors, and power management circuits, where reliability is paramount.

3. Industrial Equipment

Industrial machinery often relies on thick film resistors for their durability and performance in harsh environments, making them ideal for applications such as automation and control systems.

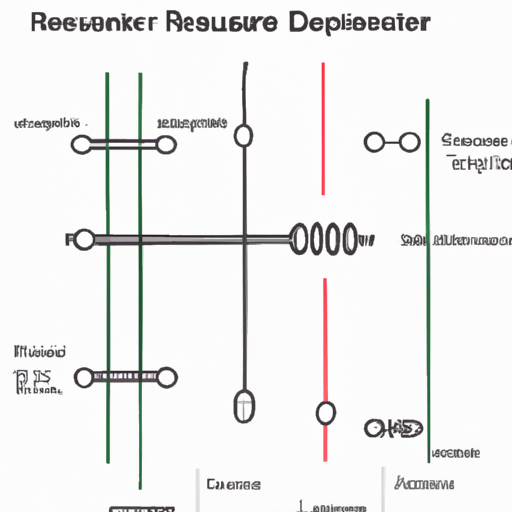

III. Key Specifications to Consider

When selecting thick film resistors, several key specifications must be considered to ensure optimal performance in your application.

A. Resistance Value

1. Understanding Resistance Measurement (Ohms)

Resistance is measured in ohms (Ω), and selecting the correct resistance value is critical for circuit functionality.

2. Tolerance Levels and Their Significance

Tolerance indicates how much the actual resistance can vary from the specified value. Common tolerance levels include ±1%, ±5%, and ±10%. Choosing the right tolerance is essential for ensuring circuit accuracy.

B. Power Rating

1. Definition and Importance of Power Rating

The power rating indicates the maximum power the resistor can dissipate without overheating. It is typically measured in watts (W).

2. Calculating Power Requirements in Circuits

To calculate the power requirements, use the formula: P = I²R, where P is power, I is current, and R is resistance. Ensuring the resistor's power rating exceeds the calculated power is crucial for reliability.

C. Temperature Coefficient

1. Explanation of Temperature Coefficient (ppm/°C)

The temperature coefficient indicates how much the resistance value changes with temperature, measured in parts per million per degree Celsius (ppm/°C).

2. Impact on Performance in Varying Temperatures

A low temperature coefficient is desirable for applications exposed to temperature fluctuations, as it ensures stable performance.

D. Voltage Rating

1. Importance of Voltage Rating in Circuit Design

The voltage rating indicates the maximum voltage the resistor can handle without breaking down.

2. Breakdown Voltage Considerations

Selecting a resistor with an appropriate voltage rating is essential to prevent failure in high-voltage applications.

E. Size and Form Factor

1. Common Package Types (e.g., SMD, Through-Hole)

Thick film resistors come in various package types, including surface mount devices (SMD) and through-hole configurations.

2. Space Constraints in Circuit Design

Consider the available space in your circuit design when selecting the size and form factor of the resistor.

IV. Environmental Considerations

A. Operating Temperature Range

1. Importance of Thermal Stability

Understanding the operating temperature range is crucial for ensuring the resistor performs reliably in its intended environment.

2. Selecting Resistors for Extreme Conditions

For applications in extreme temperatures, choose resistors specifically designed for high or low-temperature operation.

B. Humidity and Moisture Resistance

1. Effects of Humidity on Resistor Performance

Humidity can affect resistor performance, leading to changes in resistance and potential failure.

2. Choosing Resistors with Appropriate Coatings

Select resistors with moisture-resistant coatings for applications in humid environments to ensure longevity and reliability.

C. Chemical Resistance

1. Applications in Harsh Environments

In applications exposed to chemicals, selecting resistors with appropriate chemical resistance is essential to prevent degradation.

2. Selecting Resistors Based on Chemical Exposure

Consider the specific chemicals the resistor will encounter and choose materials that can withstand exposure.

V. Performance Characteristics

A. Noise Characteristics

1. Understanding Resistor Noise and Its Impact

Resistor noise can affect circuit performance, particularly in sensitive applications.

2. Selecting Low-Noise Options for Sensitive Applications

For applications requiring low noise, consider resistors specifically designed to minimize noise generation.

B. Voltage Coefficient of Resistance (VCR)

1. Explanation of VCR and Its Relevance

The voltage coefficient of resistance (VCR) indicates how much the resistance changes with applied voltage.

2. Applications Requiring Low VCR

In precision applications, selecting resistors with a low VCR is essential to maintain accuracy.

C. Long-term Stability

1. Importance of Stability in Critical Applications

Long-term stability is crucial for applications where consistent performance over time is required.

2. Evaluating Manufacturers' Specifications

Review manufacturers' specifications for long-term stability to ensure reliability in critical applications.

VI. Manufacturer and Quality Considerations

A. Choosing Reputable Manufacturers

1. Importance of Brand Reputation and Reliability

Selecting resistors from reputable manufacturers ensures quality and reliability.

2. Certifications and Standards (e.g., ISO, RoHS)

Look for certifications such as ISO and RoHS compliance to ensure adherence to industry standards.

B. Evaluating Datasheets and Technical Support

1. Key Information to Look for in Datasheets

Datasheets provide essential information about resistor specifications, performance characteristics, and application guidelines.

2. Importance of Customer Support and Resources

Consider manufacturers that offer robust technical support and resources to assist in your selection process.

VII. Cost Considerations

A. Budgeting for Thick Film Resistors

1. Understanding Cost vs. Performance Trade-offs

When budgeting for resistors, consider the trade-offs between cost and performance to ensure you meet project requirements.

2. Bulk Purchasing and Pricing Strategies

Bulk purchasing can lead to cost savings, so consider this option if you require a large quantity of resistors.

B. Long-term Cost Implications

1. Reliability and Failure Rates

Investing in high-quality resistors can reduce long-term costs associated with failures and replacements.

2. Impact on Overall Project Costs

Consider the overall impact of resistor selection on your project's budget and timeline.

VIII. Conclusion

In conclusion, selecting the right off-the-shelf thick film resistors is a critical step in ensuring the success of your electronic applications. By understanding the key specifications, environmental considerations, performance characteristics, and manufacturer quality, you can make informed decisions that enhance the reliability and performance of your circuits. Thorough research and consultation with experts can further aid in your selection process, ensuring that you choose the best resistors for your specific needs.

IX. References

For further information on thick film resistors, consider exploring the following resources:

- Manufacturer websites for datasheets and technical specifications

- Industry publications and standards organizations for guidelines on resistor selection

- Online forums and communities for discussions and expert advice on electronic components

By leveraging these resources, you can deepen your understanding of thick film resistors and make well-informed choices for your projects.